In some cases failure will result in complete loss of service as in separation of the cap from the pin or breakage of the fiberglass core rod in both cases with dropped conductors.

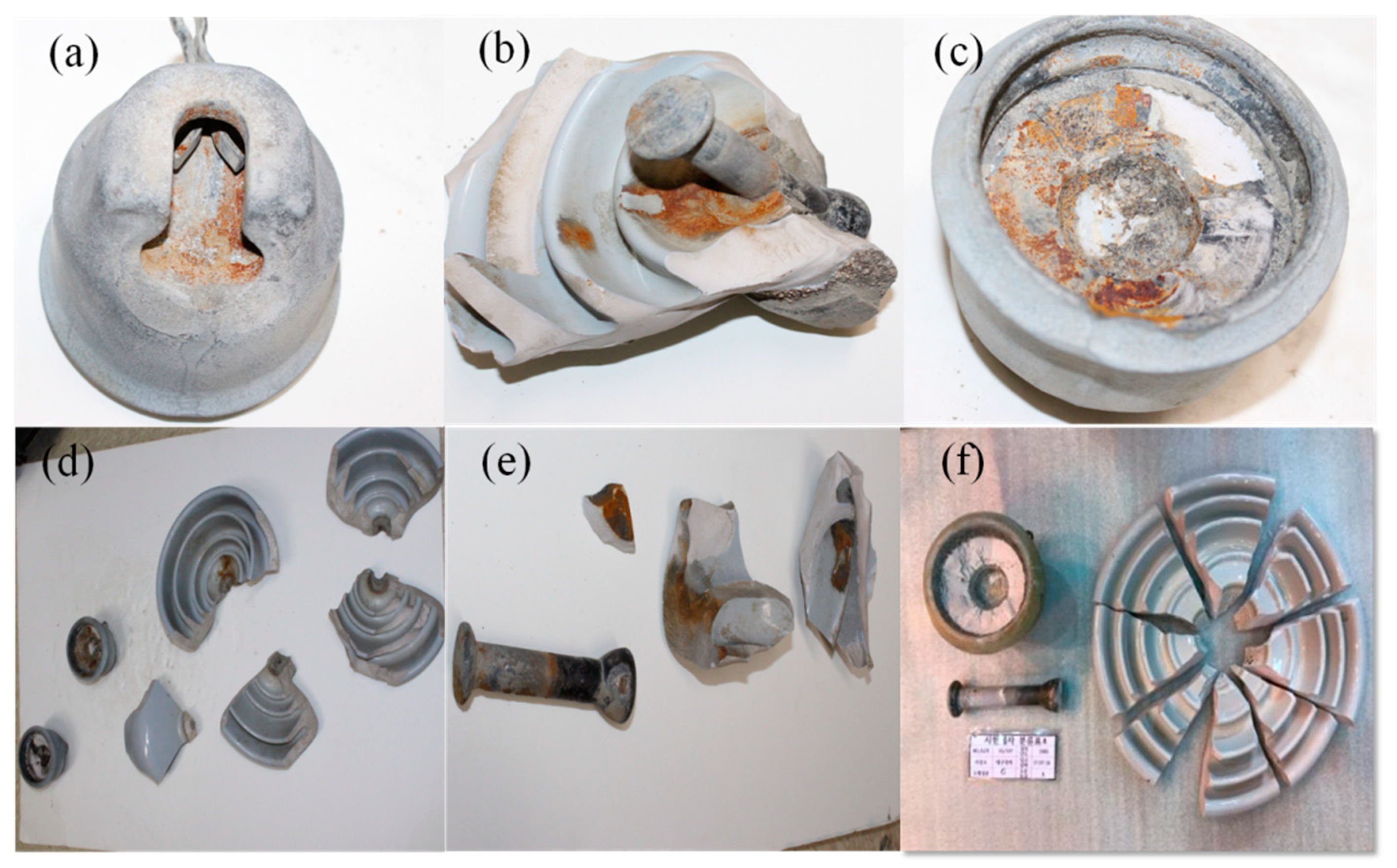

Cap and pin insulator failures.

Every porcelain insulator has a porcelain shell and cement between the cap and the pin.

Since that time similar failures have occurred on 12 47 kv 34 5 kv 41 8 kv and 69 kv bus installations at many other locations.

Mechanical failure of a composite insulator a glass or porcelain cap pin or a porcelain long rod insulator will in all cases cause a drop of the conductor if no other insulator is utilized in parallel.

These cap and pin replacement insulators are of the correct height bolt circle electrical characteristics and mounting configuration to permit direct substitution for the cap and pin or cap and pin stack.

The electrical failure of insulator occurs either by puncture or flashover.

Before going through testing of insulator we will try to understand different causes of insulator failure because insulator testing ensures the quality of electrical insulator and chances for failure of insulation depend upon.

After a period of time and expansion and contraction.

The situation becomes more complicated when an insulator fails electrically but not mechanically.

Between the socket cap and the pin of each porcelain insulator.

Download citation investigation of electrical failures in porcelain cap and pin line insulators suspension and dead end porcelain insulator strings were removed after 25 30 years in service.

The leakage current that flows through the surface of.

Causes of insulator failure.

The corrugation below the insulator is for the purpose of obtaining longer creepage path between the pin and cap.

The corrugation increases the creepage length so consequently increasing resistance to the insulator leakage current.

In typical failures that occur naturally the primary failure is degradation of the cement.

Failures of pedestal type pin and cap insulators the problem of failure of pedestal type insulators first appeared on a 34 5 kv bus at a reclamation substation in 1962.

The background of the problem and the design concepts which resulted in this new product line may be found in victor s product brochure cap and pin replacement insulators which is available from our agents or directly from the factory.

To ensure the desired performance of an electrical insulator that is for avoiding unwanted insulator failure each insulator has to undergo numbers of insulator test.

These failures which are apparently due to cement.

In other cases less serious failures might occur such as partial damage to discs or housings or shattering of the glass shell which has no immediate.

The pin of the insulator damaged the insulator thread.

In the case of a puncture the arc passes through the body of the insulator.